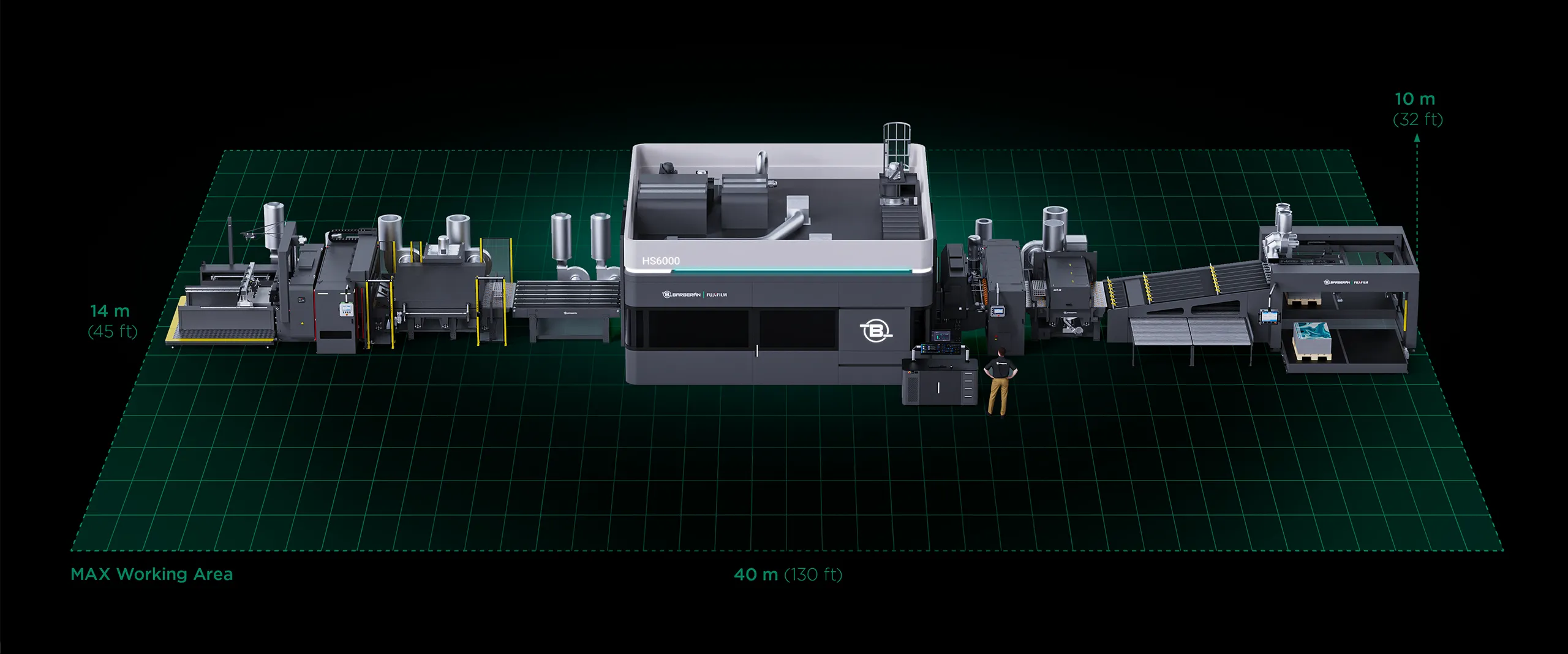

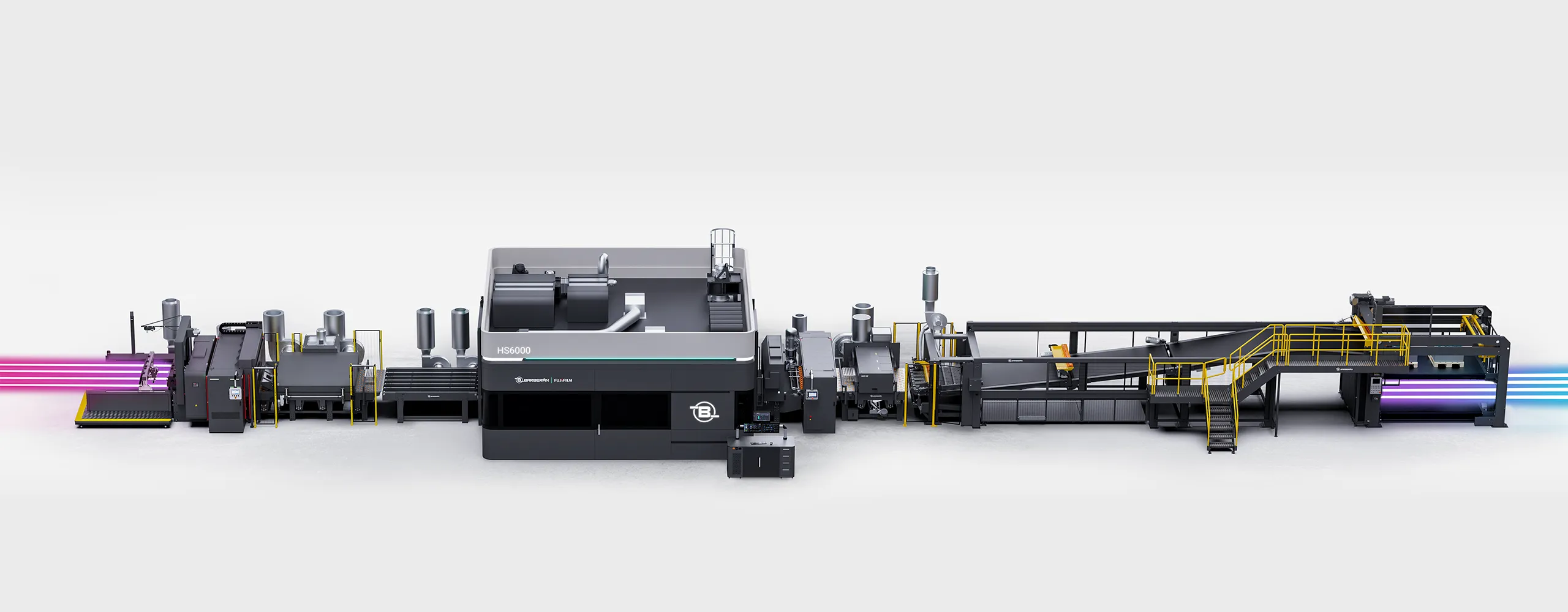

Unrivalled modularity to fit your business needs

Each press is tailor-made and built from the ground up to satisfy your specific print and business requirements. By working closely together we can create the perfect press configuration for you. These example configurations can be fully customised to meet your specific needs.

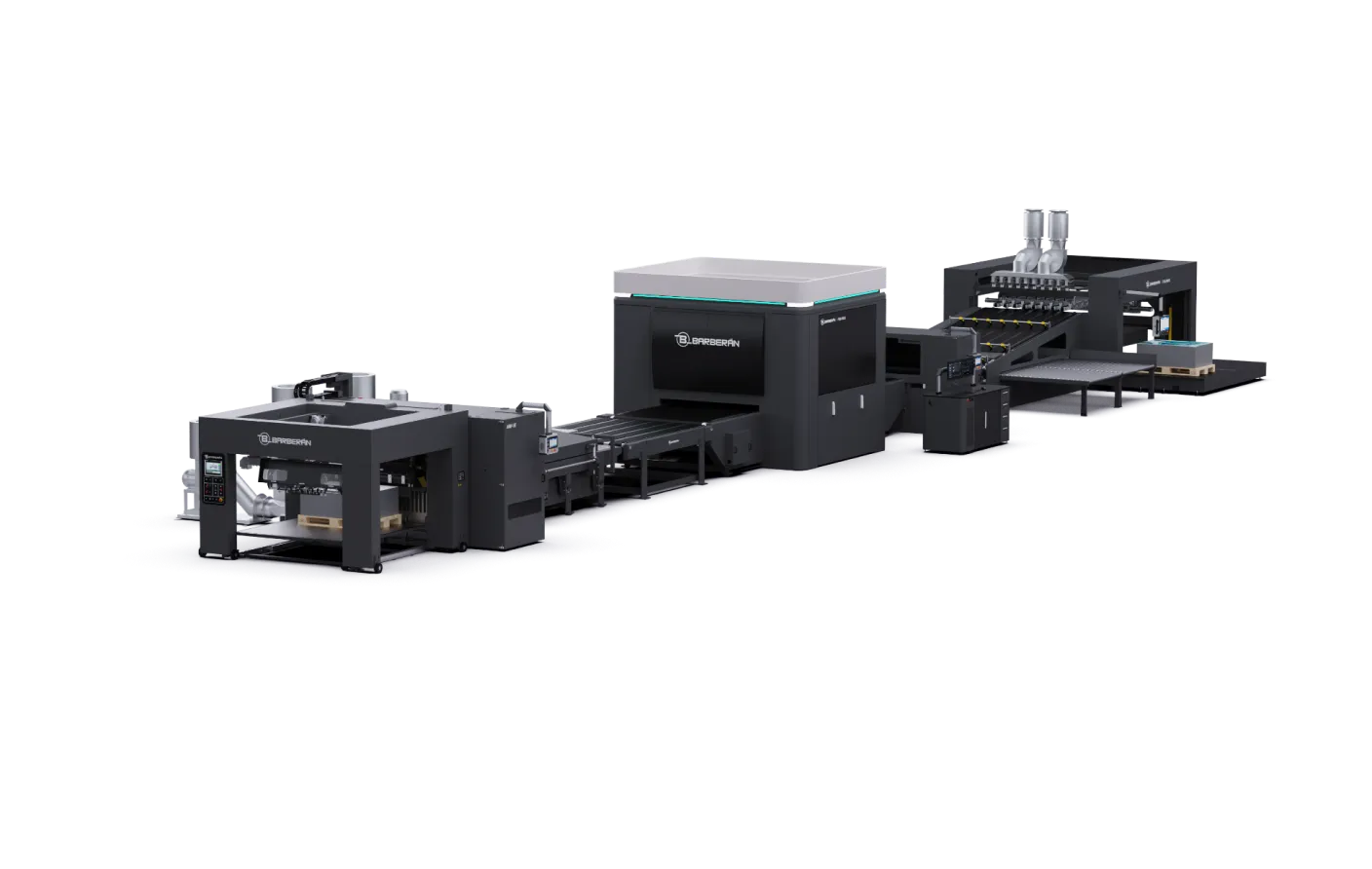

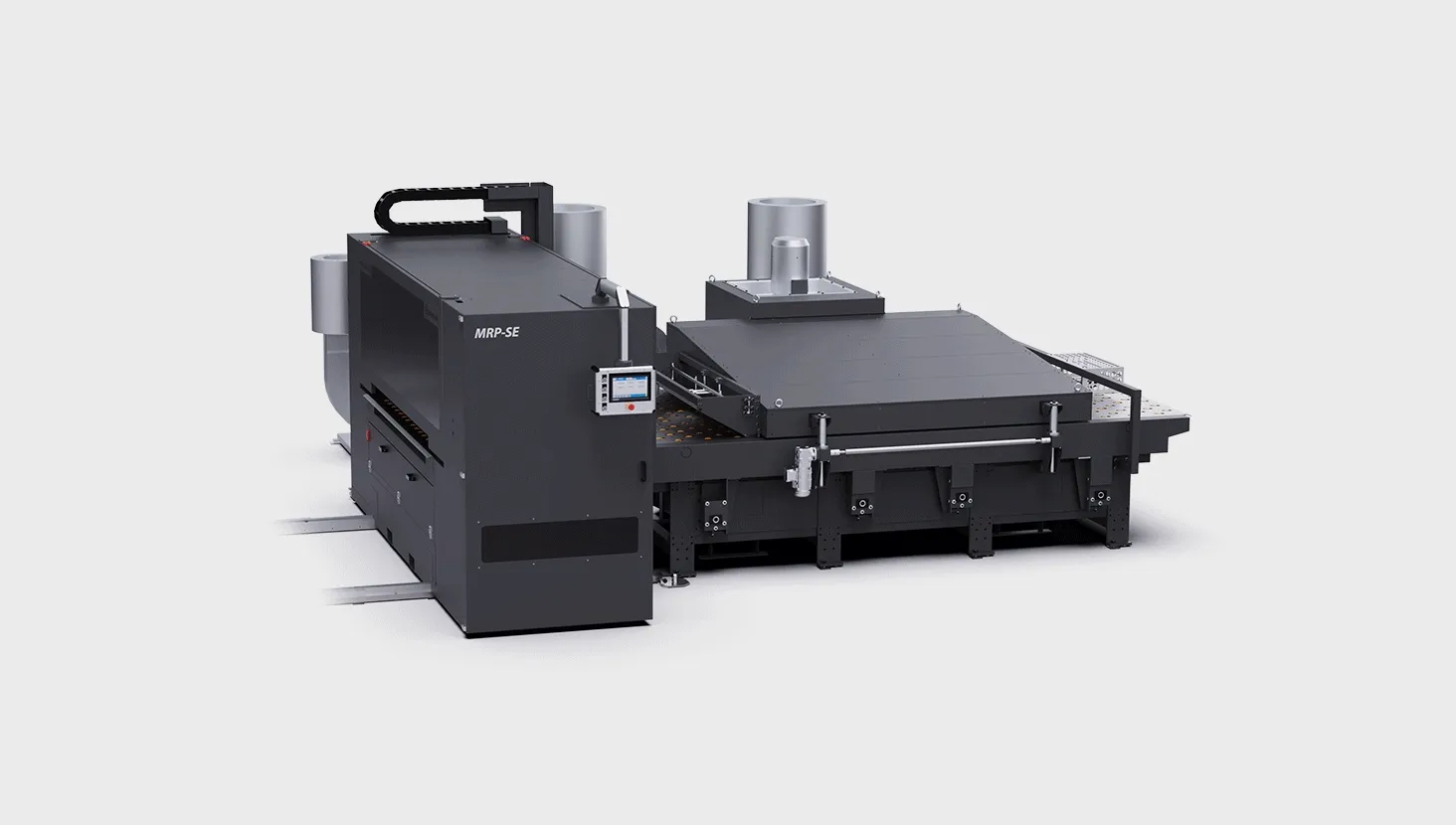

Manual feed system

Ideal for fast turnaround of shorter runs with a max print width of 1610mm and unlimited material length.

Top feed system

Ideal for fast turnaround of longer length runs with pallet-to-pallet automation and a max print size of 1610x2500mm.

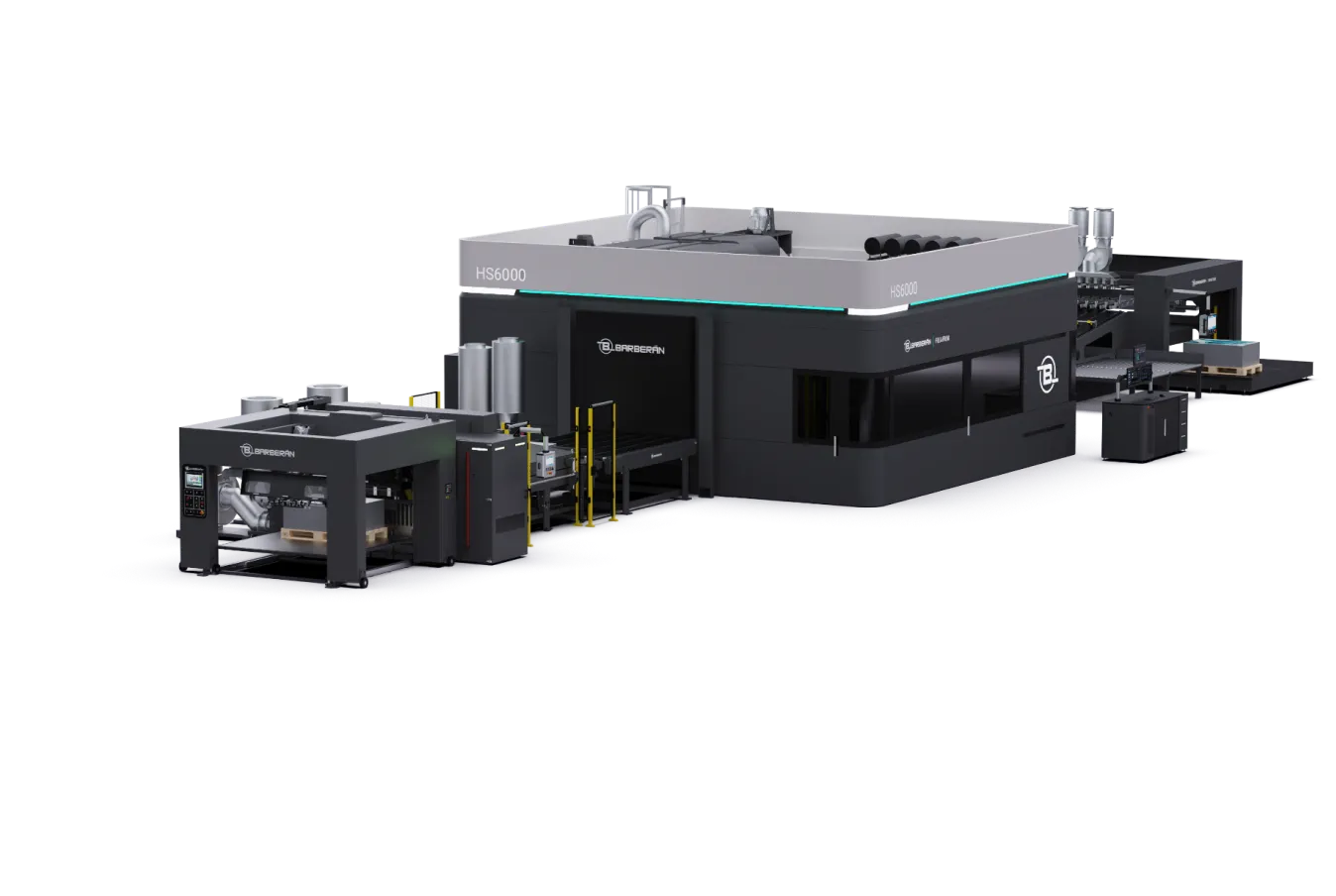

Top feed - industrial vacuum system

Optimised vacuum system for corrugated production with pallet-to-pallet automation and a max print size of 1610x2500mm.

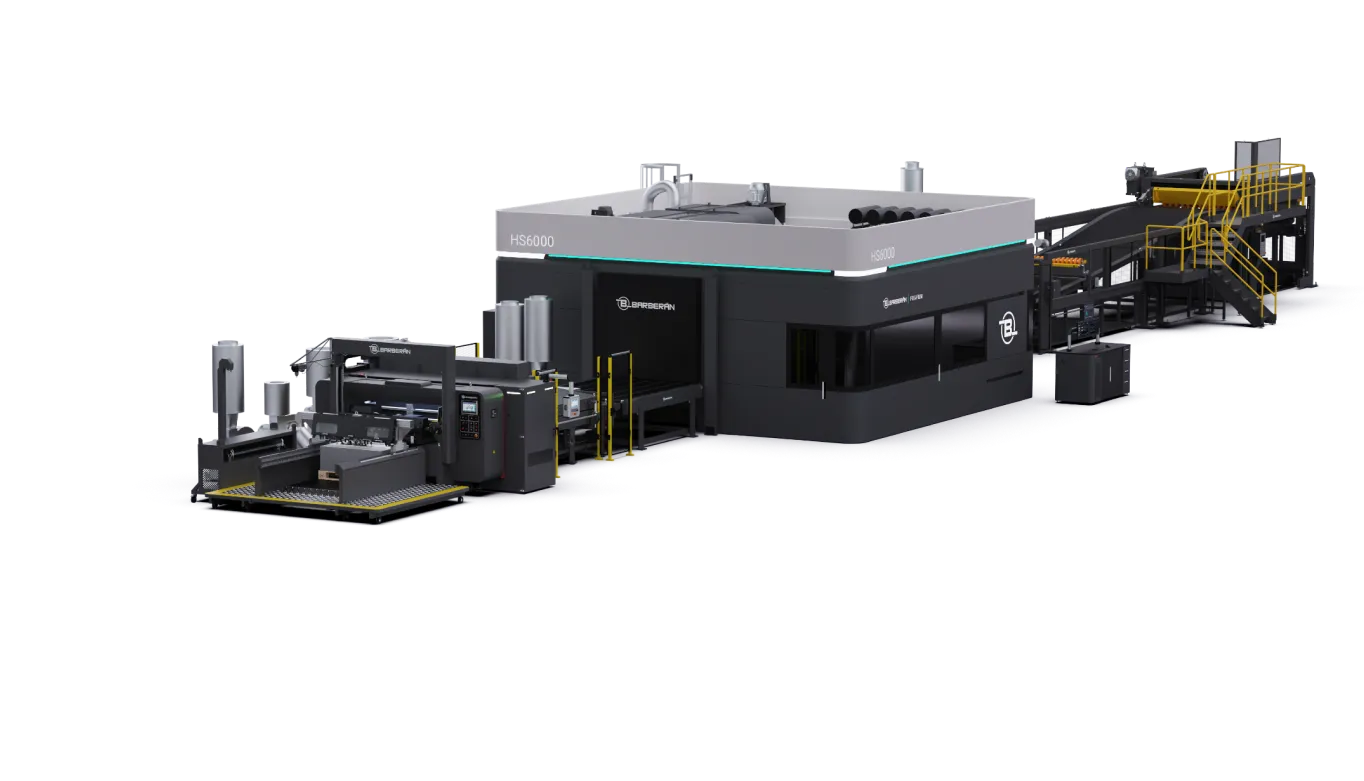

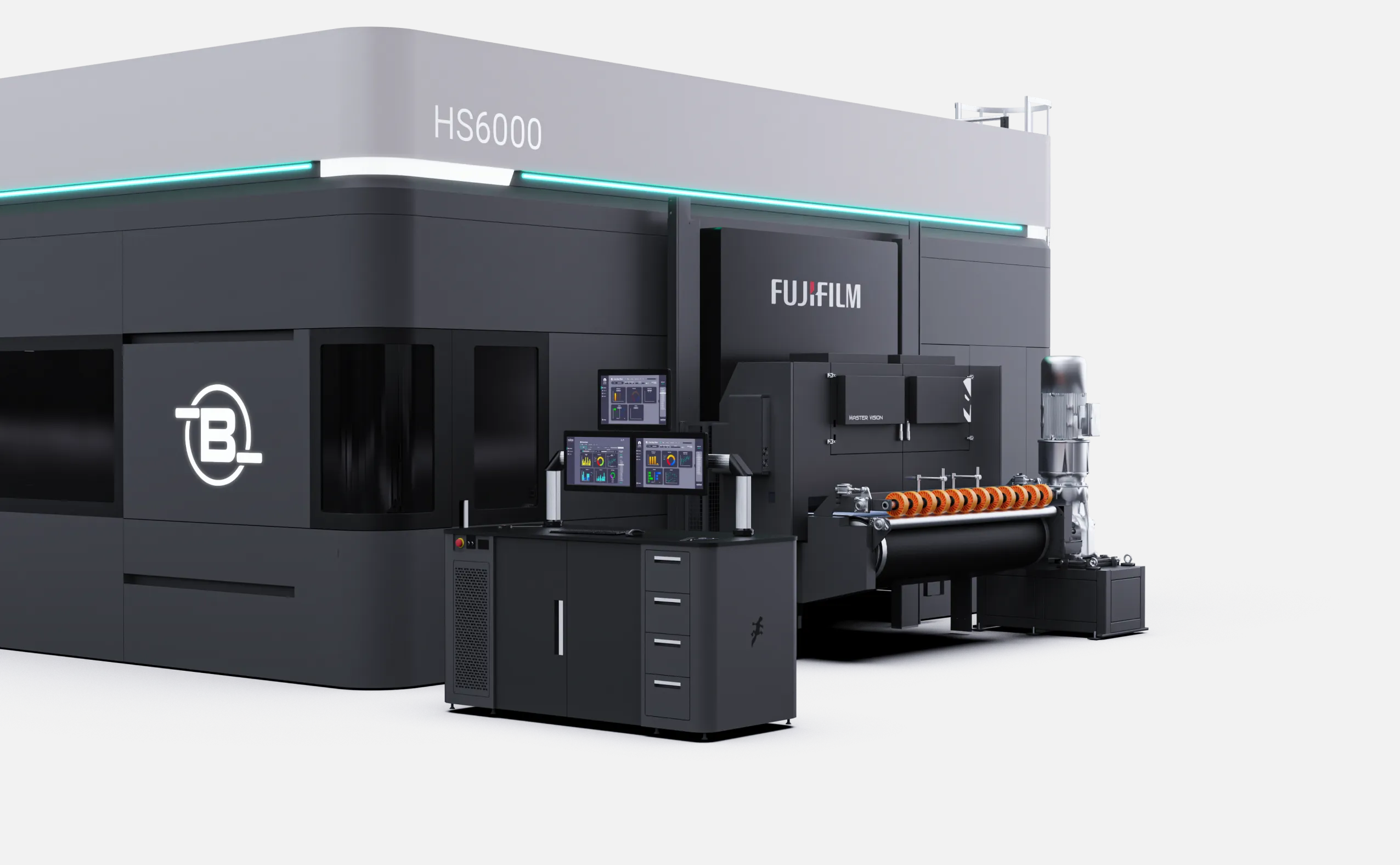

Top of the range HS6000

The HS6000 includes top feed, pallet-to-pallet automation with material up to 1700x2500mm, and bottom feed continuous production with material up to 1700x3000mm.

Experience 80m/min top feeding and 120m/min bottom feeding rates and a full host of features for high speed, continuous production.

Over

6,000 m2/hr

Speeds of up to 120m/min when bottom feeding and up to 80m/min when top feeding

600 dpi printheads

Excellent print quality even at top speeds with an optional second channel for increased productivity and nozzle redundancy.

Up to

1.6 m Print Width

With a maximum media width of 1.9m bottom feeding and 1.7m top feeding

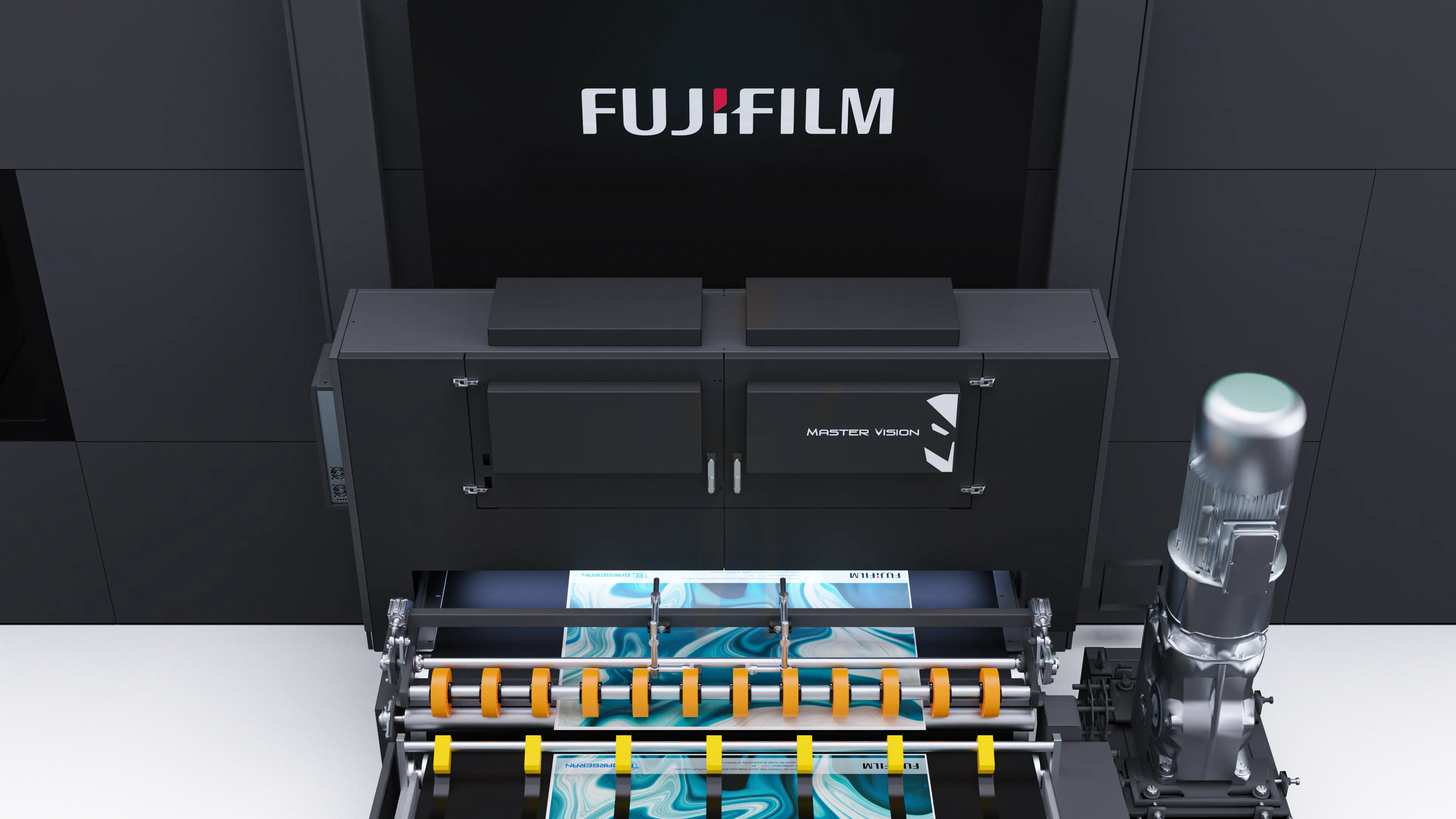

MasterVision

Intelligent system for monitoring print quality on the fly

5 pl droplet size

Capable of printing 3pt text with ease and achieving soft gradient effects.

Optimised Feeding

Our range of feed systems optimise productivity by minimising the gaps between sheets.

Media Capabilities

The HS Series is full of features designed to make operation as efficient as possible and your life easier. Maximising uptime and output while minimising ink use, energy and maintenance time for you to get through print jobs faster than ever for less.

This hybrid system combines top and bottom feeding technology to allow for a huge range of media to be fed that wouldn’t be possible with traditional single feed systems. In addition switches between top and bottom feeding are kept quick with it taking less than 10 minutes for a team of two.

Save time and material with the electronic inspection system based on artificial vision technology that is capable of automatically calibrating the printer to reduce setup time and maintain optimal conditions during production. MasterVision is able to analyse defects and introduce necessary countermeasures to address these issues on the fly.

Either control components independently or manage the entire print line from a single, central workstation. Make machine adjustments rapidly and monitor production status in a streamlined workflow using the powerful G6 print management software.

The primer features a new inline access system for maintenance and cleaning that makes the process quicker and easier than ever. By moving the primer inline rather than laterally means that alignment issues are a thing of the past and exact precision is achieved every time. In addition this system reduces the width of the working footprint.

.BvvRVv6w_Z1BwqjI.webp)

Combining Fujifilm’s ink expertise with the high resolution printheads we are able to offer exceptional colour gamut, even when running at high speeds. Increasing turnaround times and opening new opportunities.

Fujifilm’s new breakthrough technology is pushing the boundaries of inkjet capabilities. More and more materials are now able to be printed without primer, driving down costs and increasing profits.

Barberán is a Spanish family

owned industrial manufacturer of single pass digital machinery. With their

state of the art factory in Barcelona, Spain, their knowledge of industrial

applications, and the digital requirements of different market segments, they

have been a front runner in adapting to their client’s requirements, and as

a result supply machinery all over the world.

Barberán’s

expertise lies in heavy, precision engineering that is the backbone of

their industry-leading print machinery. They boast in-house manufacturing

capabilities allowing them to quickly innovate and offer tailored, service

focused customer partnerships.

For almost two decades they have

been designing and manufacturing cutting edge digital printing systems for

different market segments with a strong track record in industrial single

pass.

Fujifilm is a global leader

in print solutions due to its market defining products that focus on innovation

and state of the art technology. The company has a long history of pushing

the boundaries within the print industry that includes inventing uv inkjet

and having the world’s largest uv inkjet factory.

Fujifilm is

in wide format for the long term with an industry proven record in wide

format, multi-pass technology. The company is able to bring its extensive

market experience, knowledge of global compliance and investor backing to

this next generation printer development.

.BfxX0tOW_Z1cx6sa.webp)

.DJ8t_7tE_Z1DtAXl.webp)

Get in touch below or with your local Fujifilm sales representatives to discuss how we can help you elevate your print business with the HS Series.

Our specialist representative can guide you through the component options and help you choose a tailor-made configuration right for your business.